LB Runner Masterbatch Used in LLDPE Processing Instructions

"LB" type of rheological masterbatch is the use of high quality and efficient rheological agent, PE as the carrier, through a special process and processing of Chengdu special masterbatch.

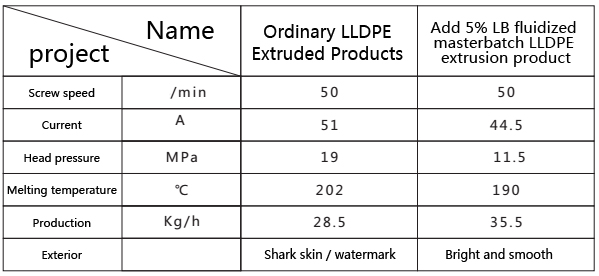

Usually in the production of LLDPE products, the production is low and the amount of material is unstable, the surface was melt fracture (shark skin). To solve such problems, our company successfully developed a fluoropolymer diluted with acetone, and then evenly mixed with the PE carrier made of new flow masterbatch. The product changes the lubricity of LLDPE resin during processing, changes the rheological condition of the thermoplastic state, reduces the melt viscosity, the processing temperature and the die pressure, eliminates the surface melt fracture, improves the product's processing stability and Smooth surface, brightness.

Technical Parameters:

1, use: rheological masterbatch and LLDPE can be used after a simple mix

2, the amount of: Masterbatch LLDPE = 1: 40

3, processing temperature: ≦ 300 ℃

3, processing temperature: ≦ 300 ℃

4, rheological masterbatch meet the US FDA standards

NINGBO LONG KANG PLASTICS TECHNOLOGY CO., LTD

Address: No.201, Dongzhao Road,Tang Jia DianIndustrialPark Zone,

Da Xu Zhen, Xiangshan, Zhejiang

TEL:0574-65622818

FAX:0574-65622958

MOB:13486663666

P.C:315706

Email:loubo@nbhl.net